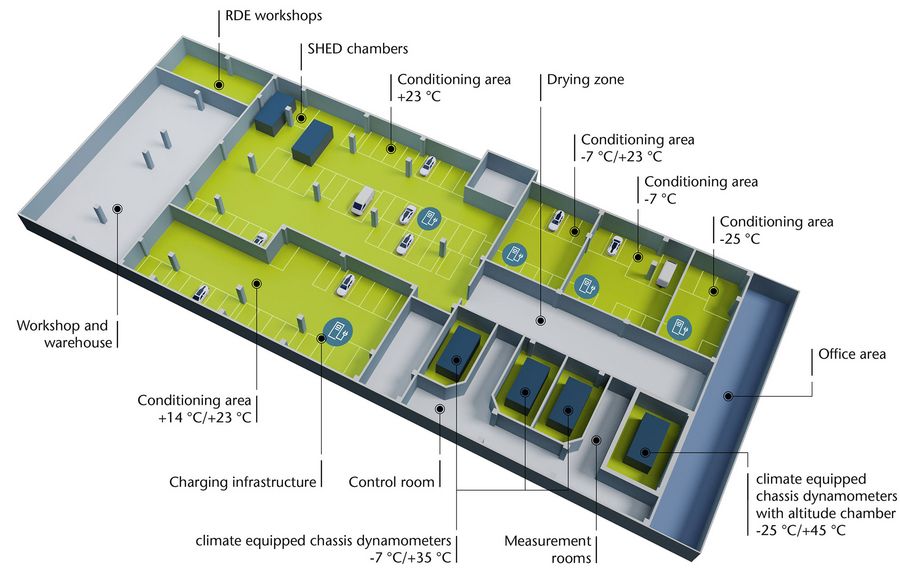

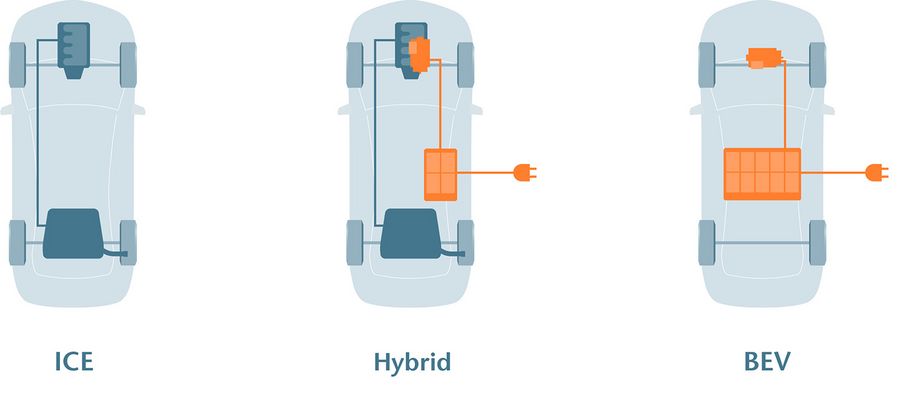

The entire world in one place. And it’s near you. State-of-the-art equipment and perfectly coordinated processes ensure a high level of reliability and superb cost-effectiveness. In striving for accreditation based on ISO 17025, we provide neutral and non-proprietary solutions for validation, certification and homologation of power train concepts of the future.