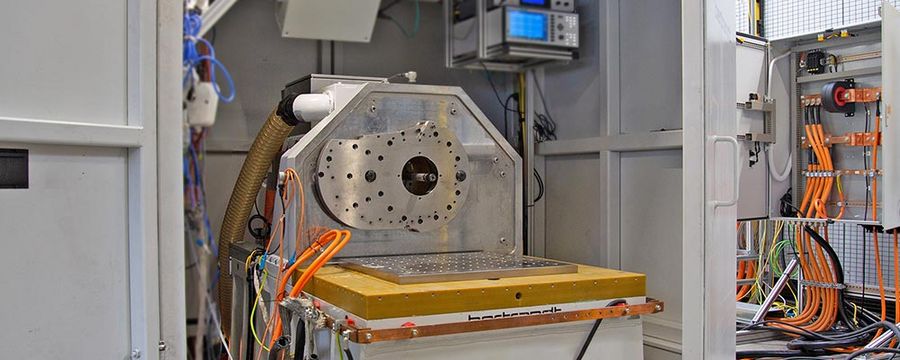

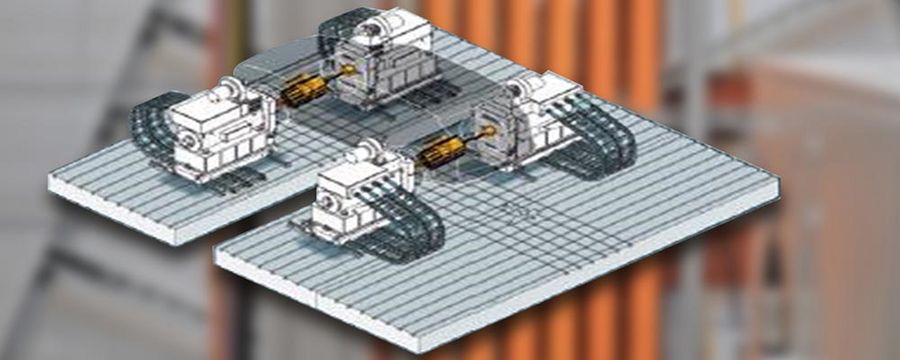

Electric motors, electric axles, electric all-wheel drive: component and system tests for your electric drive system. Bertrandt provides efficient validation on modular test rigs.

From components to modules and systems: our modular and versatile test rigs for electric motors and electric axles enable us to provide validation services for all components and systems of your electrified vehicle. Applications range from (mild) hybrids (HEV) and plug-in hybrids (PHEV) to battery-electric vehicles (BEV), including all of the electrified auxiliary drives. Would you like to find out more? Just click on the individual service fields: