The world of mobility is changing: new technologies, new usage scenarios, new markets, and new market participants. New technologies are revolutionizing the powertrains in our vehicles. Alternative usage scenarios are expanding the way in which we travel. First- and last-mile applications, shared mobility – traffic in our megacities is creating new perspectives on the way we move around and is already making entirely new demands on the mobility ecosystem. Our concept of maximum mobility is changing forever.

Electric mobility, connectivity, and autonomous driving: rapid technological development is having a huge impact on shortening development cycles. Nevertheless, we still need to meet high demands regarding functionality and safety.

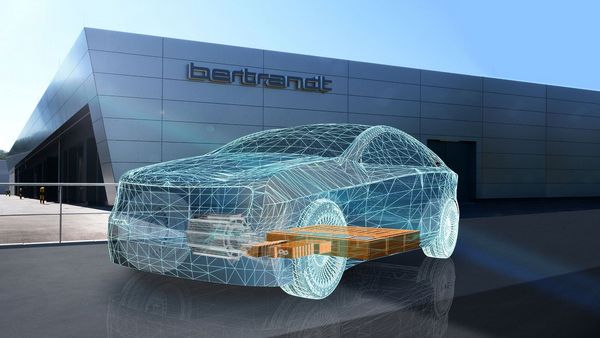

This is precisely where Bertrandt comes into play as a company and partner. As an integrated engineering service provider, we take a holistic approach to electric mobility. In addition to developing and validating the subsystems of an electric powertrain, we also consider their interactions with each other.

The increasing market share of electric vehicles and the ever faster expansion of renewable energy resources will make it vitally important to integrate electric vehicles into the energy network in the future. For that reason, we are already investing in the infrastructure required for the development and validation of the necessary charging and communication functions.

With our many years of expertise as a development partner for major automotive and industrial customers, we are closely familiar with our industries and their trends.

We keep an eye on all domains and can provide the entire development and validation process to suit your needs. As one of the largest engineering service providers, we can offer development services throughout Europe. We are a reliable and innovative partner for our customers – both today and in the future.